Revolutionizing Rice Milling Efficiency

Unlock the Power of Efficiency with our Cutting-Edge Rubber Solutions for Rice Dehusking!

Your Trusted Partner for Cutting-Edge Rubber Solutions in the Rice Mill Industry

Elevating Rice Milling to New Heights

At KK KAMSONS Products, we take pride in our commitment to delivering cutting-edge rubber solutions that revolutionize the efficiency of rice milling. Our state-of-the-art products are meticulously crafted to enhance the dehusking process, ensuring maximum yield and minimal wastage. With a focus on innovation and quality, our rubber solutions are designed to unlock the true potential of your rice mill, empowering you with unprecedented efficiency and profitability.

Our team of experts brings almost 50 years of experience and expertise to the table, ensuring that every product we create is of the highest standard. We take pride in our dedication to customer satisfaction and strive to exceed expectations with every product we deliver. We are making different grades and quality with different properties to cater to different types of Paddy and Rice Mills.

About Us

50 Long Years Of Manufacturing Excellence With Quality At It's Best!

KK KAMSONS Rubber Product for Rice Mills is a pioneering name in the rice mill industry, specializing in the manufacture of high-quality rubber Polisher Brakes and dehusking Rubber Rolls

Our team of experts including the promoter themselves brings decades of experience and expertise to the table, ensuring that every product we create is of the highest standard. Mr Vikas Bhargava the owner himself is a Management Graduate as well as Technically trained in Rubber Technology.

At KK KAMSONS, we understand the importance of consistent quality and maximum yield in the rice production process. That’s why our rubber solutions are designed to optimize dehusking efficiency while minimizing waste. Our commitment to sustainable practices also ensures that our products contribute to a greener and more environmentally-friendly rice milling industry.

Our Products

Rice Mill Industries Rubber Solution We Serve!

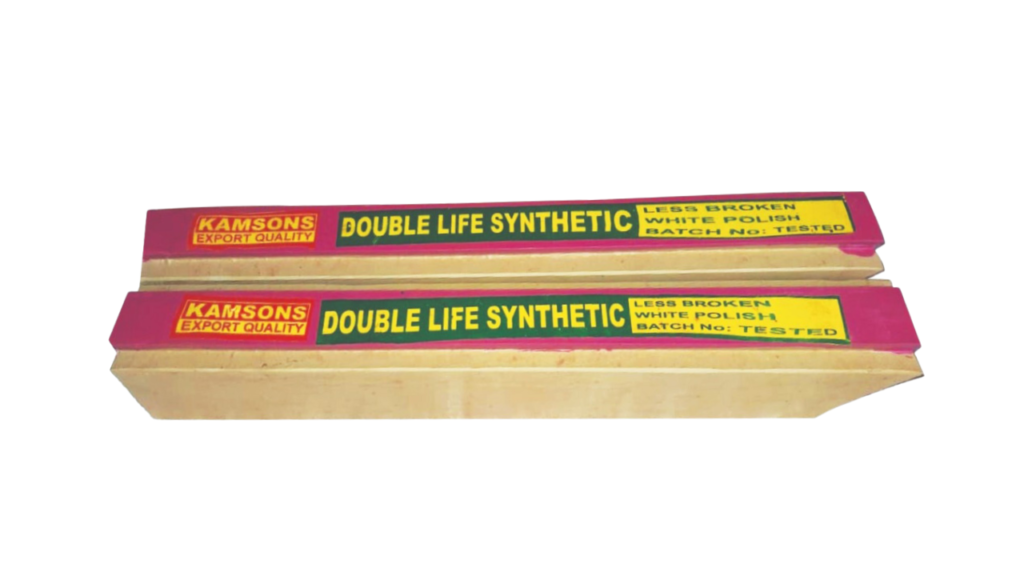

Specially Made for Basmati Rice

Our Basmati Rice Rubber Polishing Brakes are designed to enhance the visual appeal and quality of Basmati rice, one of the world’s most cherished rice varieties. These specialized rubber are super soft and naturally White in Colour to help brakes gently remove the outer layer of the rice grains, ensuring a polished finish while preserving the integrity of the grains. Crafted with the highest quality imported Rubber materials, our Basmati Rice Polishing Brakes are built for durability, reliability, and consistent performance.

Specially Made for Boiled Rice

Our Rice Rubber Polishing Brakes are designed to be long lasting and naturally smooth to add the perfect finishing touch to the rice milling process. These precision-engineered brakes gently polish the rice grains, removing the outer layer and delivering a lustrous appearance. Crafted with high-quality rubber, our polishing brakes are built to withstand the rigors of continuous use, ensuring a consistent and flawless polishing performance.

Specially Made for Muri

Our Rice Rubber Polishing Brakes are designed to be a bit hard and stout specially for Muri Rice. The brakes gives longevity and gentle polish to the grain for ensuring a longer and smoother run. We guarantee double longevity of our brakes.

Rice Rubber Dehusking Rolls

Our Rice Rubber Dehusking Rolls are the pinnacle of efficiency and precision in the rice milling industry. Crafted with the finest imported Rubbers and Chemicals, these rolls are designed to deliver exceptional performance, ensuring a seamless and effective dehusking process for paddy grains.

What Our Customers Say

"We are a Team of Skilled Professionals, Managed by Technical Experts!"

Rice Rubber Dehusking Rolls

Our Rice Rubber Dehusking Rolls are the pinnacle of efficiency and precision in the rice milling industry. Crafted with the finest quality rubber materials, these rolls are designed to deliver exceptional performance, ensuring a seamless and effective dehusking process for paddy grains.

Rice Rubber Polish Brakes

Our Rice Rubber Polishing Brakes are designed to add the perfect finishing touch to the rice milling process. These precision-engineered brakes gently polish the rice grains, removing the outer layer and delivering a lustrous appearance. Crafted with high-quality rubber, our polishing brakes are built to withstand the rigors of continuous use, ensuring a consistent and flawless polishing performance. We provide different brakes for Basmati, Muri and Boiled Rice for long lasting and smooth performance.

The only place where you’ll get the perfect solution for all your industry needs.

Contact Us

Get in touch with us today to experience the KK Kamsons difference! Our rubber solutions will take your rice milling process to new heights of efficiency and profitability.

FAQ

Our rubber polishing brakes contribute to extending the shelf life of Basmati rice. The precise polishing process reduces the bran content, enhancing the rice’s storage capabilities. When stored in proper conditions, Basmati rice polished with our brakes can be preserved for an extended period, typically up to two years or more.

While our rubber polishing brakes are optimized for Basmati rice, they can also be used with other rice varieties. We offer customization options to adapt our brakes for different rice types, ensuring consistent and effective polishing while preserving each variety’s unique characteristics. We provide different brakes with varied hardness and color for variety of different Rice.

Routine maintenance is essential to ensure optimal performance. We recommend regular inspection and maintenance, typically every 3 to 6 months, depending on your usage volume. Our products are designed for durability and easy maintenance, reducing downtime.

Yes, our rubber dehusking rolls are compatible with a wide range of rice milling machine models. They are designed to be versatile and can be easily integrated into your existing equipment, offering enhanced dehusking performance across different machines.

Absolutely. We understand that each rice mill has unique requirements. We offer customization services to tailor our rubber solutions to match the specific needs of different rice mills, ensuring optimum performance and efficiency.

Our rubber solutions are crafted using eco-friendly materials, reducing resource consumption and minimizing wastage during the rice milling process. This contributes to a more environmentally sustainable and greener rice milling industry, aligning with modern ecological practices.

Yes, we offer on-site technical support for the installation, maintenance, and troubleshooting of our products. Our team of experts is dedicated to ensuring that you get the most out of our solutions and can provide valuable assistance when needed.

The durability of our rubber solutions is a result of our meticulous material selection, precise engineering, and quality control. We use high-quality rubber materials that are specifically chosen for their wear resistance, ensuring long-lasting performance even under heavy workloads.

The lead time for orders can vary depending on the specific product and order size. Typically, our products are manufactured and delivered within [mention typical lead time], ensuring timely delivery to meet your requirements.

Our products enhance dehusking efficiency, reduce wastage, and improve the quality of rice, leading to higher yields and increased market value. Additionally, our customized solutions and technical support ensure that your rice milling process operates at peak efficiency, ultimately boosting overall profitability.